Business Overview

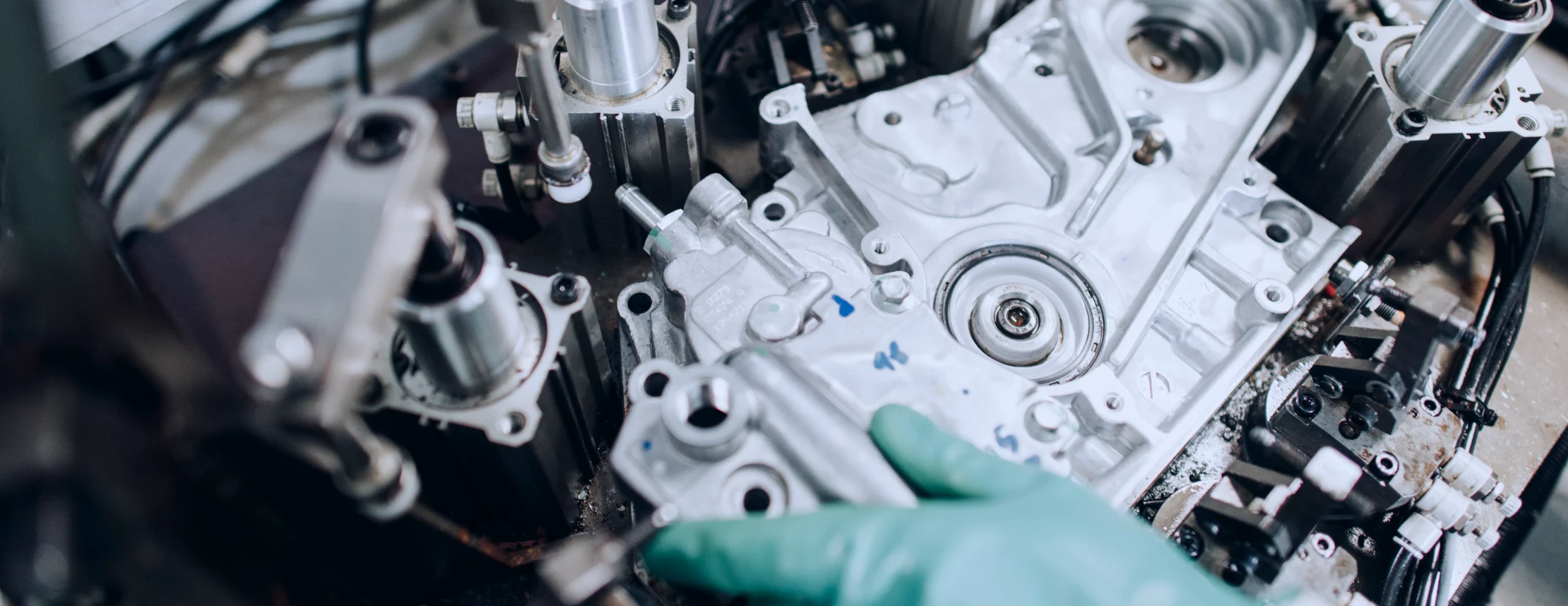

The Company and its subsidiaries are engaged in the manufacturing of automotive parts for the automotive industry, such as passenger cars, pickup trucks, trucks, and agricultural machinery. The main customer group includes Original Equipment Manufacturers (OEM) both domestically and internationally,

with long-term purchase agreements in place. The Company focuses on creating added value for the organization and stakeholders through differentiated products. The Board of Directors is responsible for setting policies for the Company, which are implemented by the executives in each division. These executives must report their operations to the Chief Executive Officer. Each company sets its business strategy goals, and progress is jointly monitored through Management Committee meetings.

Corporate Performance Highlights

Shareholding Structure

Core Competencies

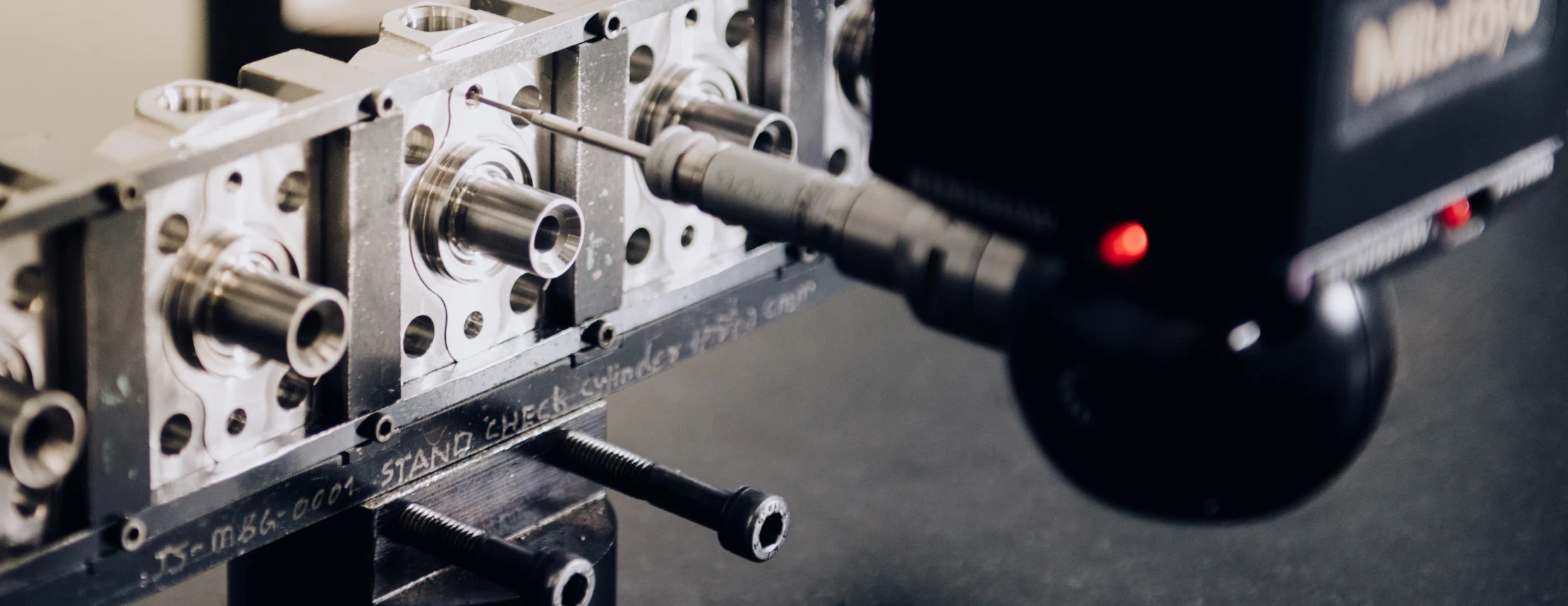

Design & Development

Tool & Equipment Manufacturer

Low, Mid and High Volume Production