About PCSGH

P.C.S. Machine Group Holding Public Company Limited (“the Company” or “PCSGH”) manufactures and distributes forged steel parts, aluminum forging parts, molds, as well as metal processing and transformation, metal products, engine parts, transmission systems, brake systems, suspension systems, metal parts for vehicles, and metal parts for electronic products, including aluminum die-casting parts.

Currently, the Company invests in shares of three subsidiaries operating in Germany and Hungary, namely P.C.S. Machine Group Holding GmbH (“PHG”), P.C.S. Smart Mobility GmbH (“PSM”), and P.C.S. Smart Energy GmbH (“PSE”), which are under the same control as the Company's shareholders.

Total vehicle production

units

Total Pickup truck production

units

Domestic vehicle sales totaled

units

Vehicle exports totaled

units

Vision

The Manufacturer of Choice for Customers with World Class Quality

Companies in the P.C.S. Machine Group Holding are committed to being the Manufacturer of Choice for Customers by creating maximum customer satisfaction and building trust and sustainable relationships between the company and customers by delivering worldclass quality products and impressive services.

Mission

To achieve business success in alignment with its vision, the company recognizes its mission toward all stakeholders. This mission encompasses the following key aspects:

Premium Quality for Customer

Corporate Governance for Social

Shareholders Benefits for Shareholder

Global Supply for Growing with Business Partners

Happy Workplace for Satisfied Employees

Corporate Culture

Organization Chart

Business Overview

The company and its subsidiaries are engaged in the manufacturing of automotive parts for the automotive industry, including passenger cars, pickup trucks, trucks, and agricultural machinery. The main customer group consists of Original Equipment Manufacturers (OEMs), both domestic and international, with whom the company has long-term purchase agreements. The company focuses on creating added value for the organization and its stakeholders through a differentiated product portfolio.

ONE-STOP SERVICES

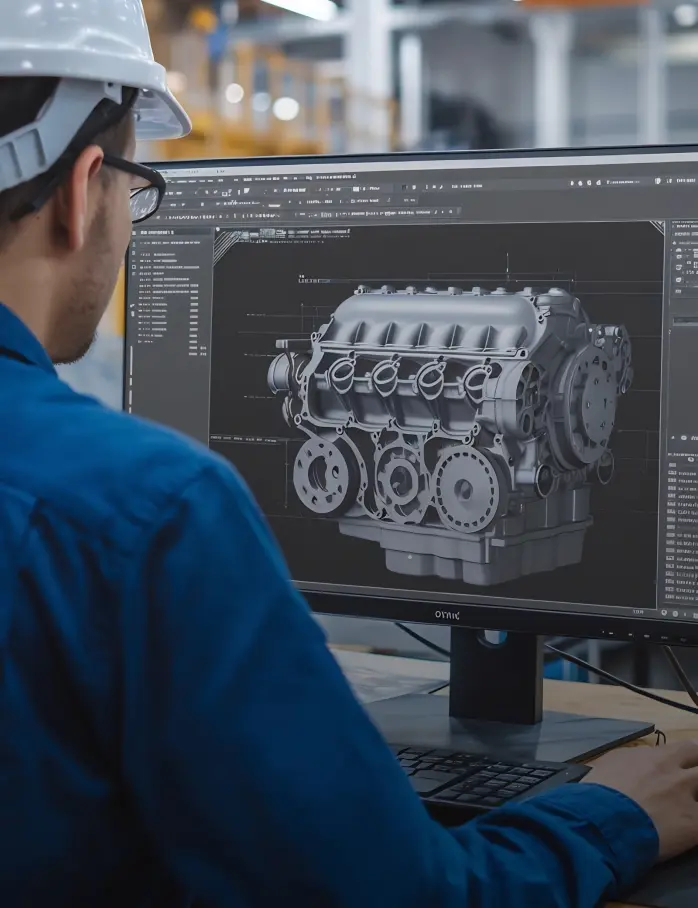

Design & Development

In-house design & development center with over 100 engineers utilizing state-of-the-art technology such as Catia, UG, Solidworks, AutoCAD. Magma Flow for fuid analysis and finite element analysis for force simulation.

Tool & Equipment Manufacturer

Tool & Die manufacturing for prototyping and mass production for cast and machined components. In-house production of special machines such as leak-test and induction hardening units.

Low, Mid and High Volume Production

Complete machining of powertrain & chassis components including heat treatment, gear making, assembly, cleaning and inspection to OEM specifications.

Validation & Testing

Complete set of test and inspection equipment to validate material condition and critical product characteristics.